GUANGZHOU HAOZHI INDUSTRIAL CO., LTD.

GUANGZHOU HAOZHI INDUSTRIAL CO., LTD.

- Home

- About Us

-

Products

-

Machining center series

-

Engraving and Milling Spindle

-

Dental Milling Spindle

-

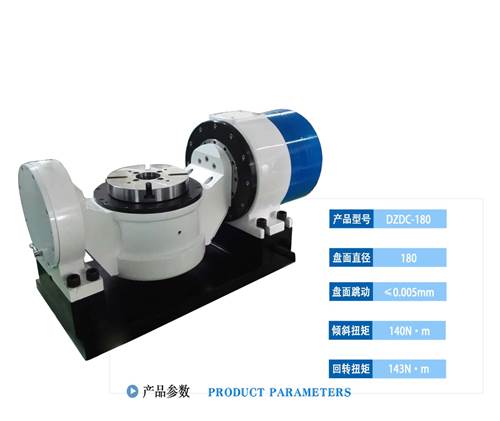

Rotary Table

-

Reducer

-

Core functional parts of the robot

-

PCB Spindle

-

Glass Grinding Spindle

-

Belt Driven and Direct Driven Spindle

-

Super Finish Spindle

-

Motorized spindle series for drilling and tapping center

-

Hydraulic static spindle series

-

Grinding Spindle

-

Lathe Spindle

-

Woodworking Spindle

-

Tool Holder

-

Collet

-

Linear motor series

-

Automated fixture (outside)

-

Automated fixture (inside)

-

Digital Controls

-

Servo Motor

-

Bending machine control system

-

Servo Driver

-

Fuel cell compressor

-

- Service

- Investor Relations

- News

- Contact Us