On October 10, 2018, Guangzhou HaozhiIndustrial Co., LTD. (hereinafter referred to as "Haozhi Industrial")held the "Intelligent Efficient Ultra-precision" opening dayactivities of future factory of intelligent manufacturing successfully. Thefactory opening day activities included the general introduction of the historyand culture of the Company, the visiting of production basis, subject symposiumand dinner party, which gave the experts and customers within the industry acomprehensive understanding of Haozhi Industrial and showed them thecompetitive strength of Haozhi Industrial in product quality, research,manufacturing management, and maintenance service, etc.

1

EfficientUltra-precision High stability

Philosophyof Products of Haozhi Industrial

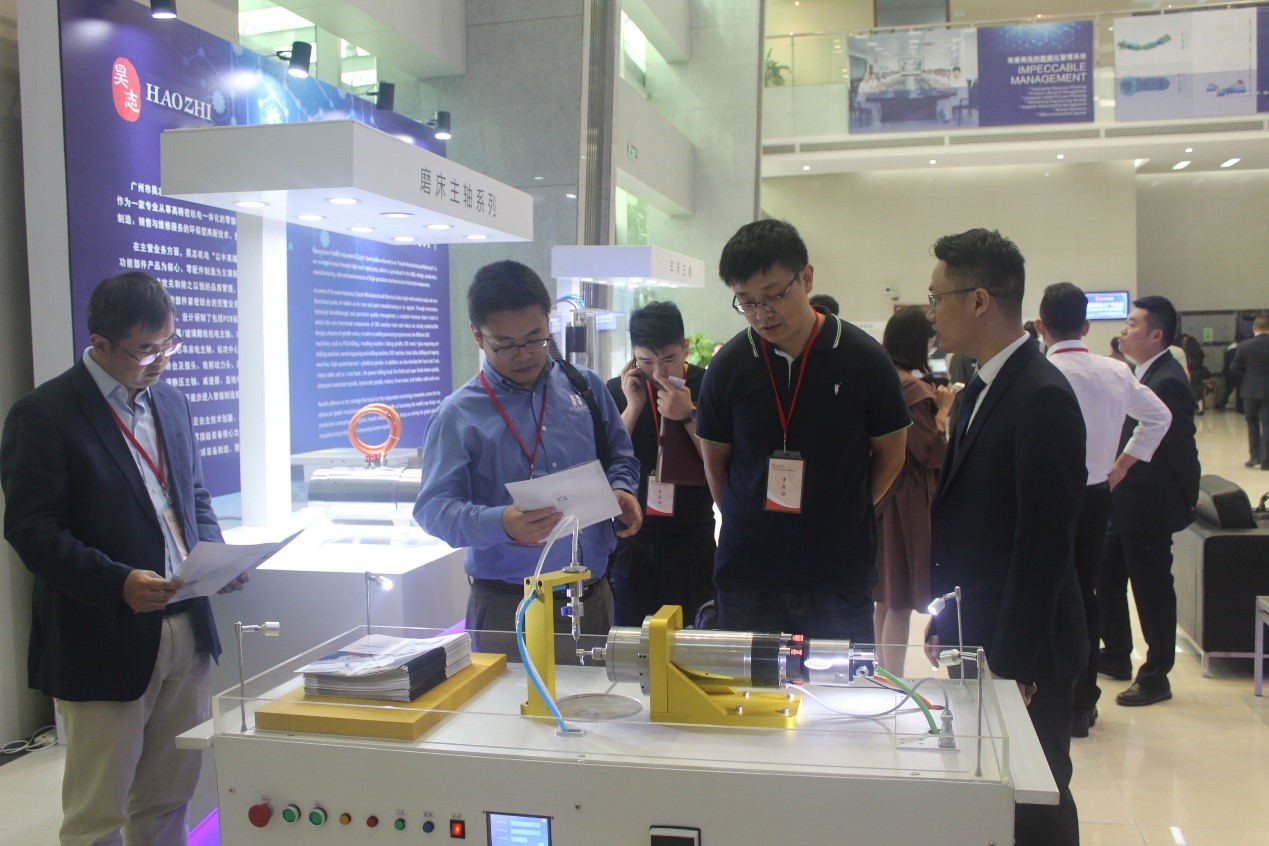

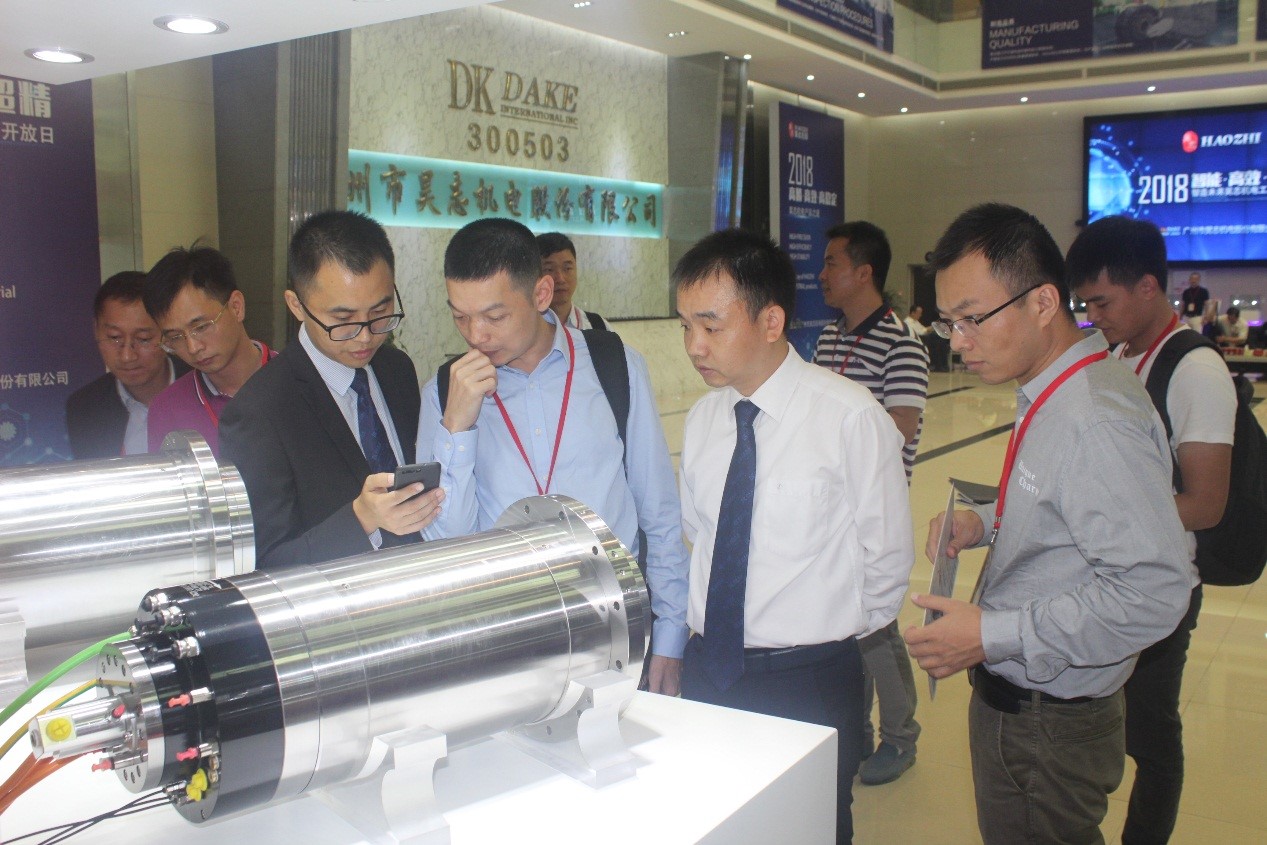

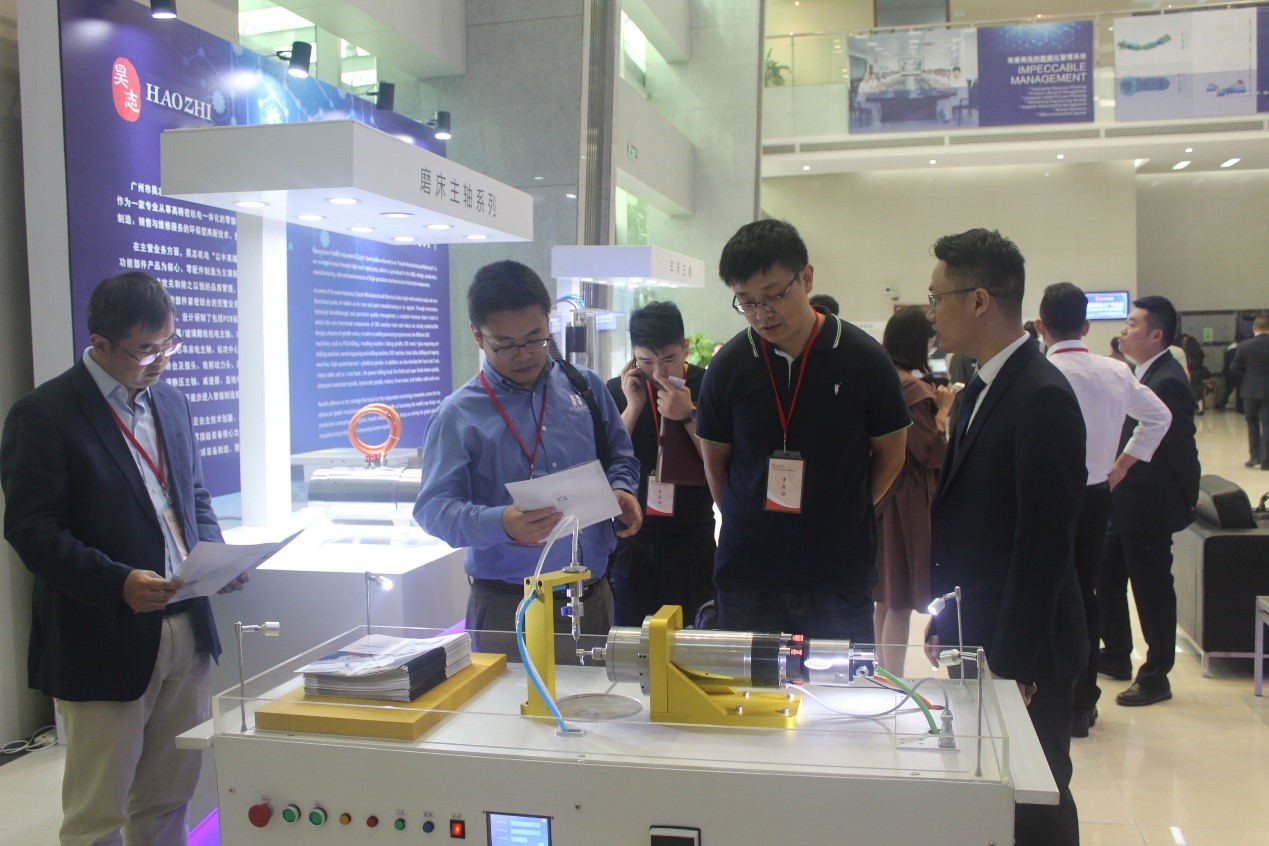

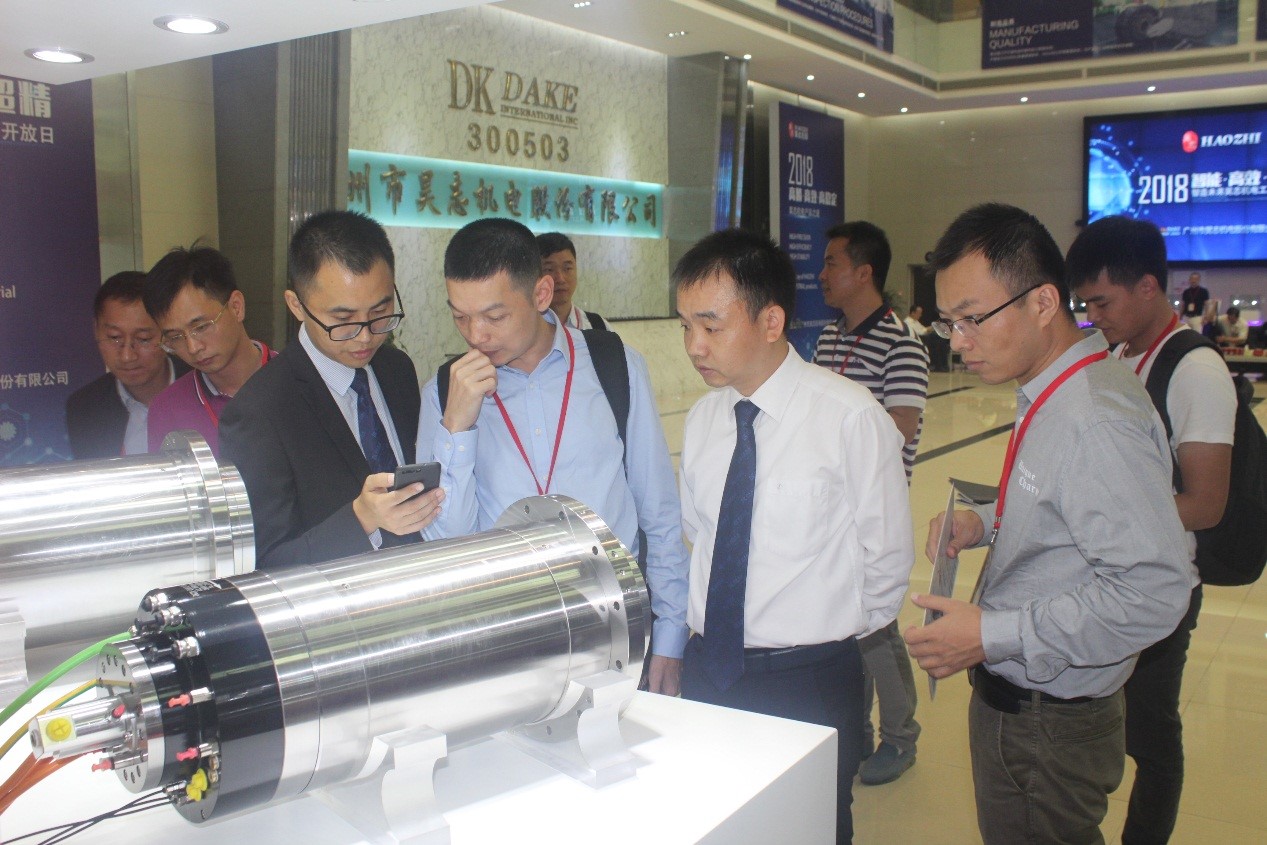

At the beginning of the activities, thebright exhibition hall and various exhibition items drew the attention of theparticipants. With regard to primary businesses, the service system of HaozhiIndustrial was "with the middle and high end machine tool and robot corefunction component products as the core and spare parts as a support".Through persistent efforts to make breakthroughs in technology and qualitymanagement, a complete business chain was built with CNC machine tool and corefunction components of robot integrated closely.

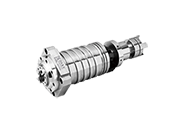

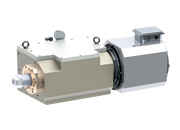

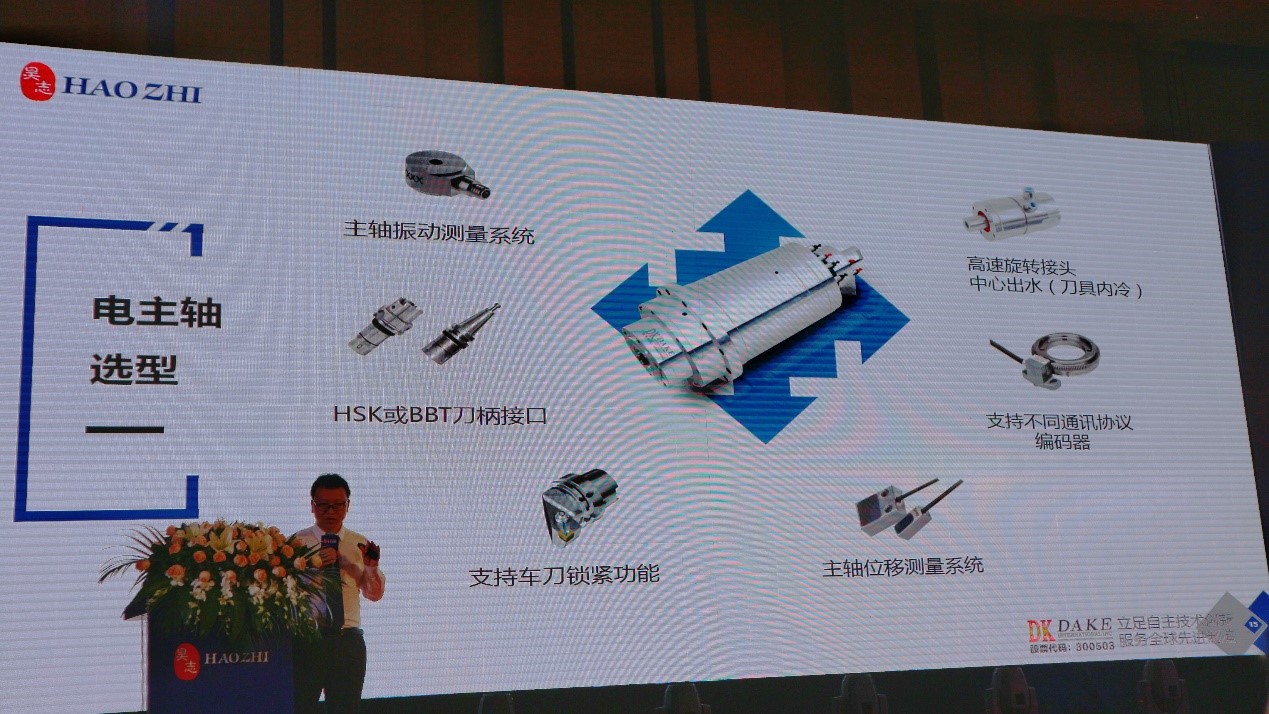

To meet the processing requirements ofvarious machine tools, Haozhi Industrial had developed dozens of series ofspindle products such as PCB drilling machine/ electric spindle of moldingmachine, electric spindle of CNC metal/glass engraving and milling machine,electric spindle of wood engraving and milling machine, spindle/electricspindle of CNC lathe, electric spindle of CNC precision automatic lathe, directdrive and belt-driven mechanical spindle, CNC series electric spindle, electricspindle of drilling and tapping center, spindle of high-speed cylindricalgrinder, CNC rotary table, milling power head, high-ray and ultra-precisionelectric spindle, ultrasonic electric spindle, hydrostatic pressure spindle,retarder, ultra-precision clamper, linear motor, shank collet, etc. and isready to step into fields relevant to intelligent manufacturing gradually.

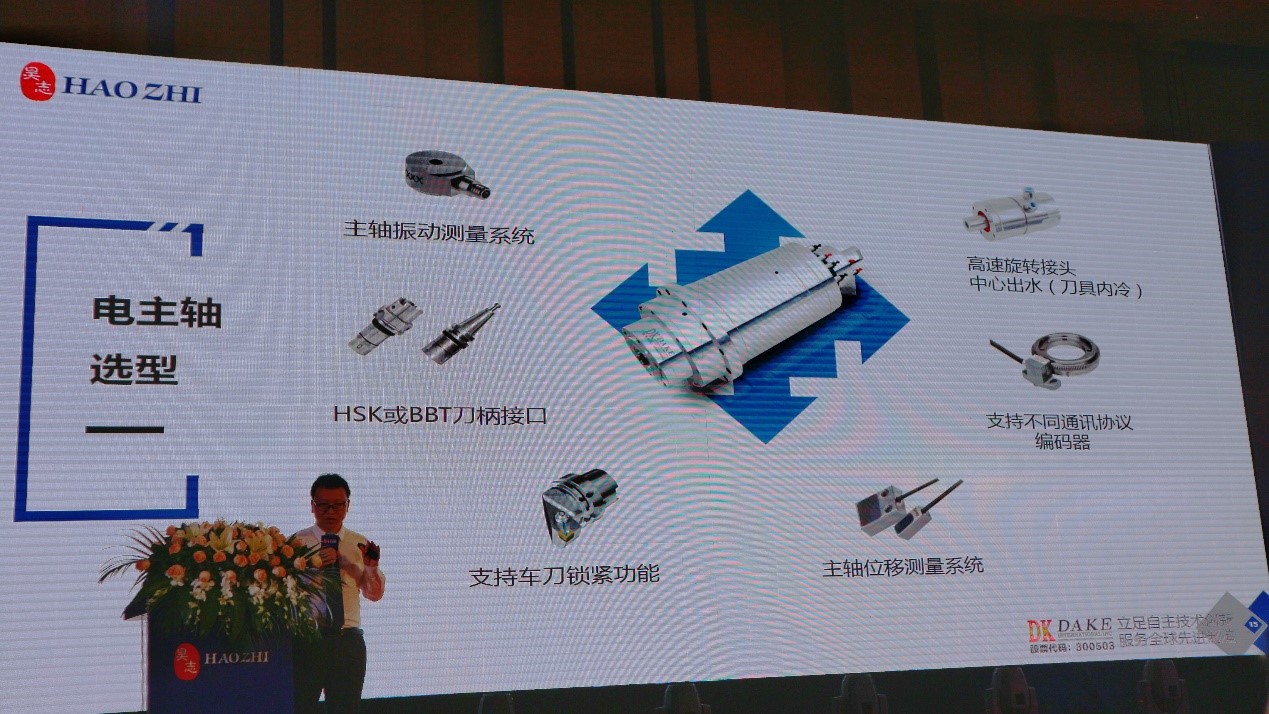

As the leader of the electric spindleindustry, the domestic market share of Haozhi Industrial already reached 40%,which ranked first nationally. CNC electric spindle shall ensure its highstability through all kinds of technologies while being high precision andefficient. For example, the service life of the bearing can be increased to alarge extent with floating forging structure, sealing structure of dynamicpressure of shaft and oil-air lubrication technology; Self-developed forgingstructure could increase the life service of the cutter changing mechanism ofthe spindle to more than 5 million times, and advanced motor sealing techniquecould lift up the protection grade of the motor, which all contributed to theunified good quality of the spindle. In addition, multiple choices providedpersonalized solutions to customers.

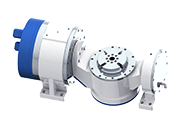

The properties of rotary table productswere also excellent. DDR rotary table could realize efficient processing.Compared with ordinary DDR, the motor with high torque developed by HaozhiIndustrial on its own had 42.7% higher power density, 61.5% higher torque and ahigh precision positioning function of which the positioning precision reached±10 arc-seconds and the repetition precision reached ±2 arc-seconds; it wasequipped with powerful brake mechanism with good airtightness and stability,which guaranteed the precision of the whole machine from multiple aspects. Bynow, multiple product series such as vertical four-spindle, horizontalfour-spindle, single arm five-spindle and cradle type five-spindle series hadbeen developed.

2

StrongR&D Team

Mastercomplete technical process

Just as such advantageous products mustrely on strong R&D team, such strong R&D strength must depend onconsiderable R&D investment. According to the introduction of Mr Leiqun,deputy general manager of the Company, the R&D expenses of the Company wasmore than 8% of the operating revenue averagely.

Through long-term operation andaccumulation, the Company had already established an advanced R&D systemand a perfect R&D platform, built a R&D team with high quality andmastered the complete technical process relevant to design and manufacturing ofthe spindle and rotary table and other products, and its R&D strength andtechnical capacity was leading in the whole country. Up to now, HaozhiIndustrial had over 300 R&D personnel, among which there were more than 70masters and doctors who mostly came from colleges and universities under 985program and owned over 400 authorized patents with rich R&D experience.

In the respect of product design,Haozhi Industrial adopted up-to-date digital protype technology and boasted themost advanced talent training system and R&D team within the industry. TheCompany made the design of the products more systematic, digital andprocess-oriented with the help of PLM and CAPP system.

All such input and efforts made inresearch and development improved efficiently the theoretical level of theTechnical R&D and the storage of cutting-edge technology of HaozhiIndustrial, which provided a strong foundation for the production ofhigh-quality products.

3

ZeroDefect of Product Quality

"Tomake each employee under control"

At present, Haozhi Industrial had twomanufacturing bases of Jiangdong Factory and Tianyuan Factory. During thevisit, the clients saw that the environment in the factory was clean and tidy,that there was strict requirement to each production link, that the employeesperformed the duties by itself. Such efficient and systematic manufacturing andproduction mode relied on the MES system equipped to the factory.

The personnel responsible forexplanation introduced to the customers that the MES system could help eachemployee obtain the data and information they need for collaboration quickly.Working drawings were all displayed by the screen to realize paperless officeand all the information in the manufacturing process was recorded to facilitatethe tracking of processing procedure. The Company provided guarantee toprecision processing through complete grasp of production needs, productionresources and production targets, thus improving production efficiency to alarge extent.

In addition, Haozhi Industrialformulated strict quality testing standards for different spare parts andproducts in strict accordance with international standards and requirements andthose within the industry to ensure zero defect of the product quality and madethe customers feel secure to use the products. The Company persisted inchoosing international leading brand as the raw material supplier for all keyproduct components and all raw material shall go through strict qualityinspection before being put into storage.

Haozhi Industrial had been committed toforging advanced and perfect processing and manufacturing workshop to providesolid guarantee for the quality of products after processing through strictimplementation of ISO9001 quality management system and ISO14001 environmentmanagement system.

4

SpecialService Mode

Put theneeds of the customers first

Maintenance service was another featureof Haozhi Industrial. Haozhi Industrial provided comprehensive maintenanceservice not only for the products of their own company but also for the spindleproducts of other companies. The Company could also provide training in respectof product operation, maintenance, and repair for customers in need.

For studying the use experience of endusers, Haozhi Industrial set up a special testing and analyzing team to makebasic research on items such as processing application, etc. to search forimprovement programs with customers to promote the quality of products. Whencustomers met abnormal application, the Company could find the radical causequickly and accurately in accordance with the experience accumulated before andtried its best to provide perfect service to the customer.

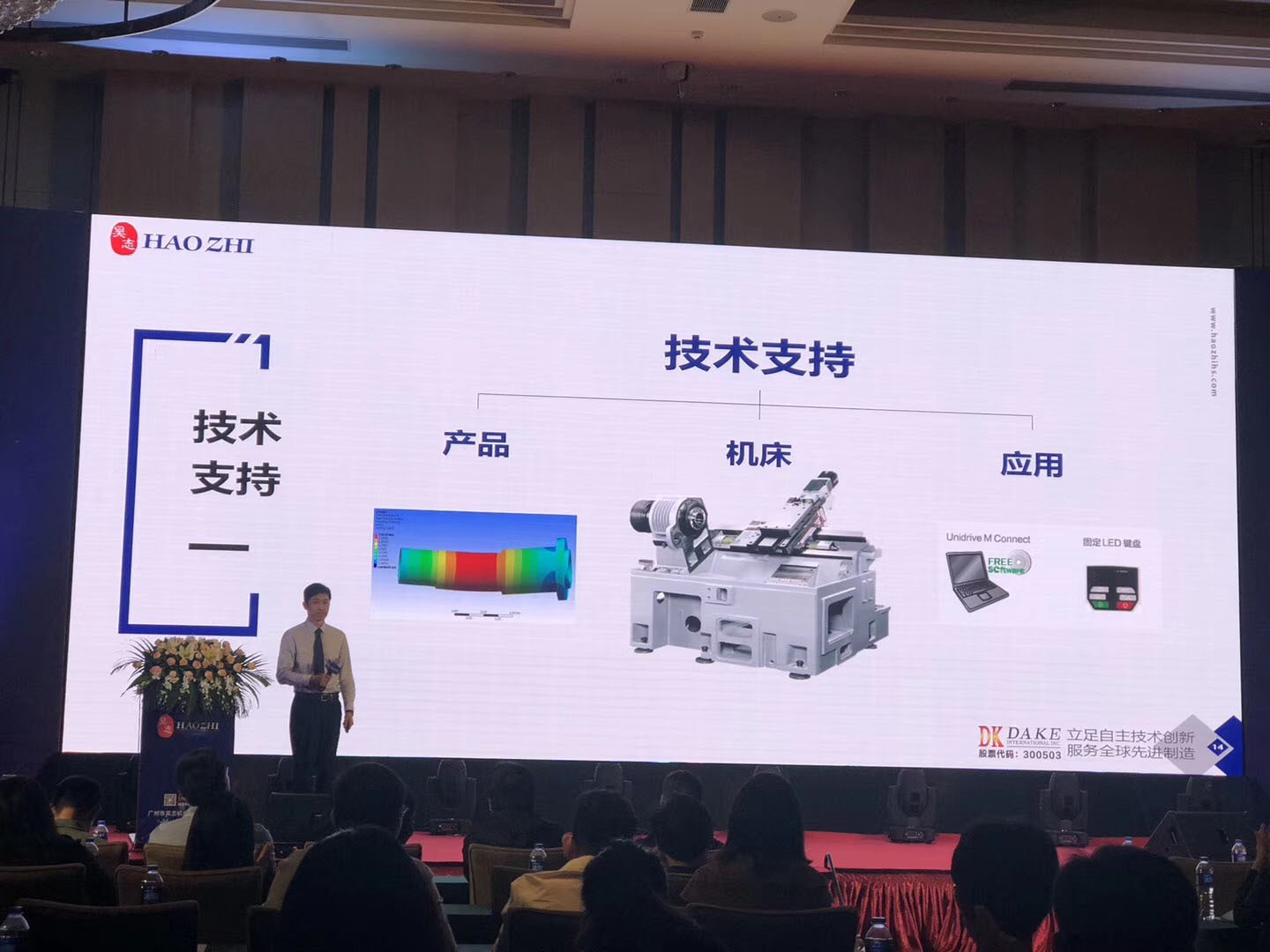

When the visit of the factory ended,the participants went to the meeting hall of the hotel to take part in thesubject symposium held there. At first, Mr Tang Xiuqing, the founder of HaozhiIndustrial, made a speech on the stage and extends his welcome and thankssincerely to all the experts and guests for their attending in the"Intelligent Efficient Ultra-precision" factory opening dayactivities of the future factory of intelligent manufacturing and elaborates onthe development history and brand meaning of the Company, the spirit of HaozhiPeople and the culture of Haozhi Industrial. Later, Mr Yu Ying, assistant tothe General Manager of Beijing FANUC Industrial Co., Ltd. and Mr Wang Xiaohui,the representative of retrospected their cooperation history with HaozhiIndustrial for so many years and shared their achievements.

Mr TangXiuqing, the founder of Haozhi Induatrial

Mr YuYing, assistant to the General Manager of Beijing FANUC Industrial Co., Ltd.

Mr Wang Xiaohui, representative of Hardinge Asia Limited

Mr Wang Xiaohui, representative of Hardinge Asia Limited

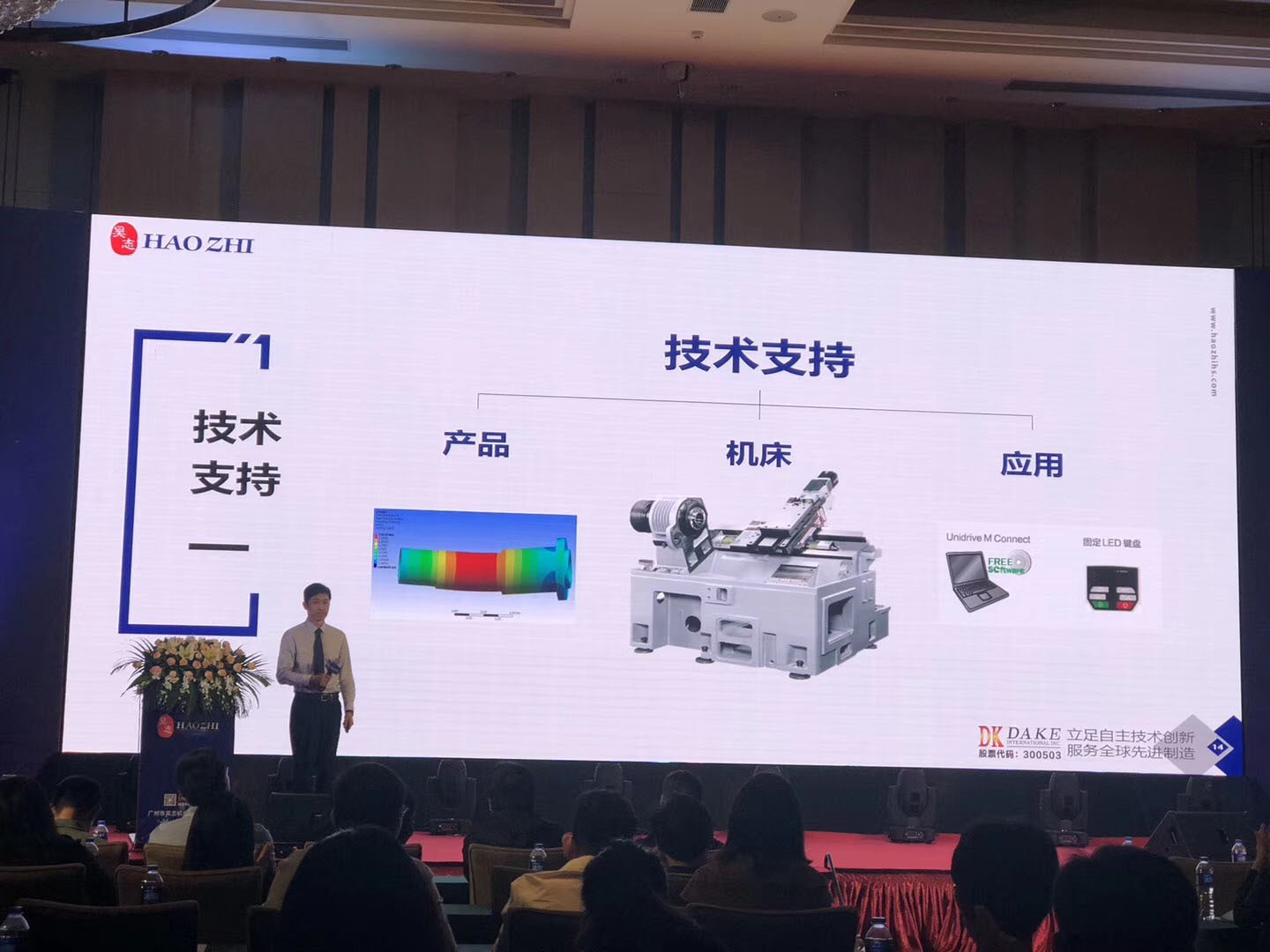

In the end, Haozhi Industrial sharedtheir knowledge about the turning and high-ray technology, CNC electricspindle, rotary product technology and precision processing application andstudy, etc. to help the participants know more about the products and servicesof the Company.

After the symposium, the Companyprepared sumptuous dinner for participants. Mr Tang Xiuqing, the founder of theCompany started the dinner by toasting to all the people.

During the dinner, Haozhi Industrialarranged splendid programs, games for interaction and lucky draw activities.People participated in the games proactively and the atmosphere there was quiteactive.

With the dinner coming to an end, thefactory opening day activities of Haozhi Industrial was going to endsuccessfully. We hoped that the image perfectly displayed this time might leavea deep impression to experts and guests within the industry from all over thecountry. Haozhi Industrial would forge ahead while staying true to its originalaspiration to become a world-leading company for the design and manufacturingof the core function components of various equipment.

GUANGZHOU HAOZHI INDUSTRIAL CO., LTD.

GUANGZHOU HAOZHI INDUSTRIAL CO., LTD.